Plaese wait

Plaese wait

Valverbe produces its filtered herbal teas according to a logic that goes from the seed to the finished product.

One of the most important phases of this process is the drying of herbs that leads to multiple factors linked to conservation, aroma and content of active ingredients of the finished product.

The drying process entails significant chemical and physical changes in the plant tissue and the dehydration process stabilizes them blocking all degradative enzymatic processes that affect the plant from the very first moments after its cutting.

Our company invested in this phase by purchasing a cool dehydration plant, the only one in Italy, with CFT® technology that, unlike the traditional hot dehydration process, keeps the cellular membrane intact together with all of the plant properties.

This technique recreates inside the drying chamber the conditions of evening breeze, that moment when due to the physical-botanical laws regulating the plant world, there is an exchange between the aerial part and the radical apparatus of the plant through the opening of cellular stomata that are closed during the day to defend themselves from the heat.

Our plant was programmed to dry approximately 8 quintals of fresh plants in 48 hours.

The freshly harvested plants are placed in a hermetically closed steel structure, with a cool and dry air flow which – thanks to the conditions described above – quickly stimulates the opening of stomata and the outflow of the water contained in the tissues.

In 2006 Valverbe performed – on two samples of herbs dried with the two different methods – a first step of sensory research through triple blind panel tests, and in the meantime a comparison on the active ingredients present in two samples of herbs dried with the two different methods.

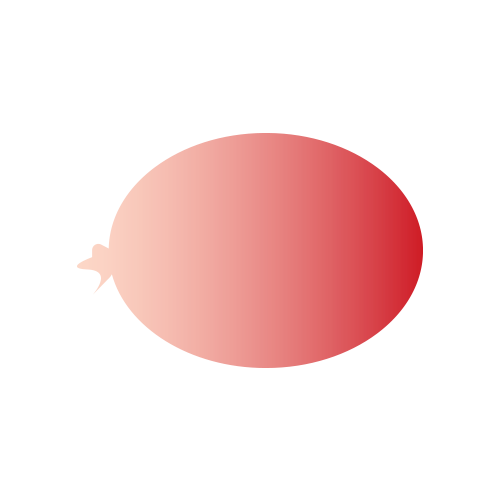

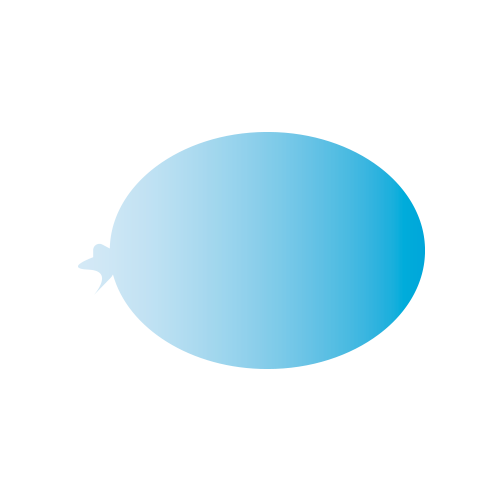

Integral cell membrane

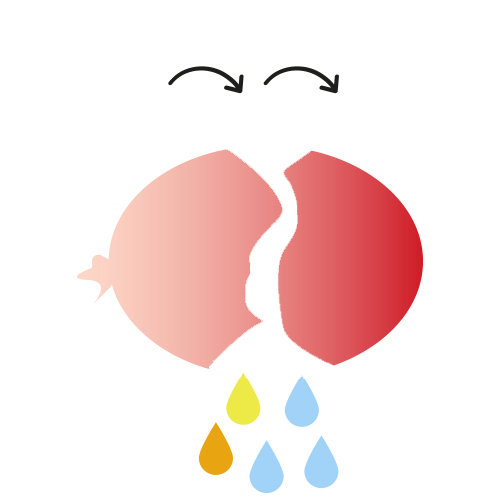

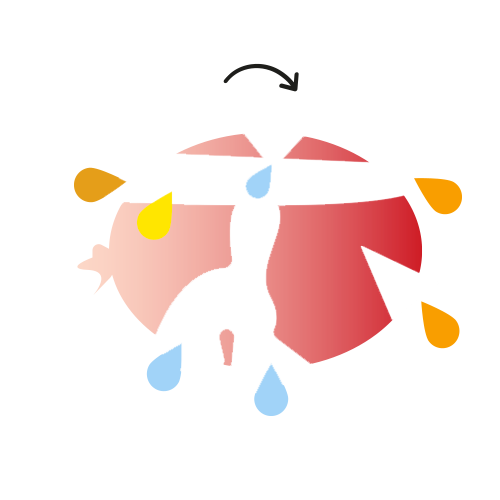

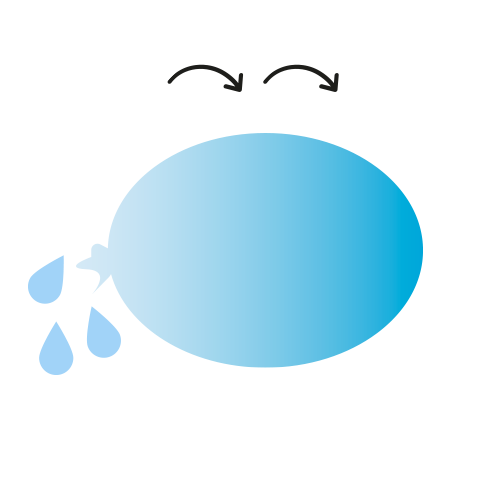

Rupture of the membrane and leakage of the liquid (6 – 8 hours of mechanical action)

Disruption of the cellular membrane with rupture of botanical sequence

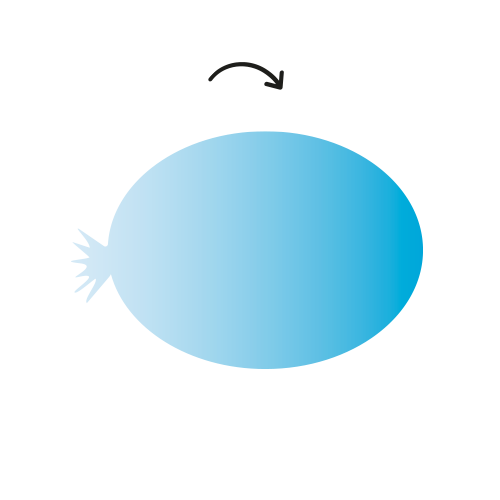

Integral cell membrane

Opening of cellular stomata with leakage of vegetation water

The cellular membrane is intact and the stoma remains open

To sanitize its herbs, Valverbe performs a cycle of abatement of the bacterial load with a silo heated at 115°C which takes the mixture of herbs at a temperature of about 80°C for 3 minutes. This process does not harm the organoleptic properties and the active ingredients of the plants since it works in the absence of moisture (compared to regular saturated steam systems). The processed product is packed in 10 kg disposable bags ready to be packaged.